ATD Cardox System

The Cardox Tube is loaded with a chemical Pressure Gas Generator and is then sealed with the Tube Head. The Discharge side of the tube is loaded with a Copper Washer and Shear Disc, followed by the operator’s choice of Discharge Head.

A Look Inside

ATD Pressure Gas Tubes are designed to handle the adverse conditions found in pyro-processing. Our tubes are made from the best material available and are designed as one continuous piece of steel. The molecular structure of the tube provides a good memory when subjected to high heat applications. Each tube is issued a serial number after it passes a complete inspection. ATD records the original casting and parameters of every tube manufactured. We use these records for future testing to insure your tubes remain in good safe working condition.

The Filling Station

The Wall-mount Filling Station is designed to free up space in the room or area it is installed. The Filling Station is constructed with a state of the art liquid transfer pump and components enabling the operator to fill the Pressure Gas Tube with liquid CO₂ in just over 30 seconds.

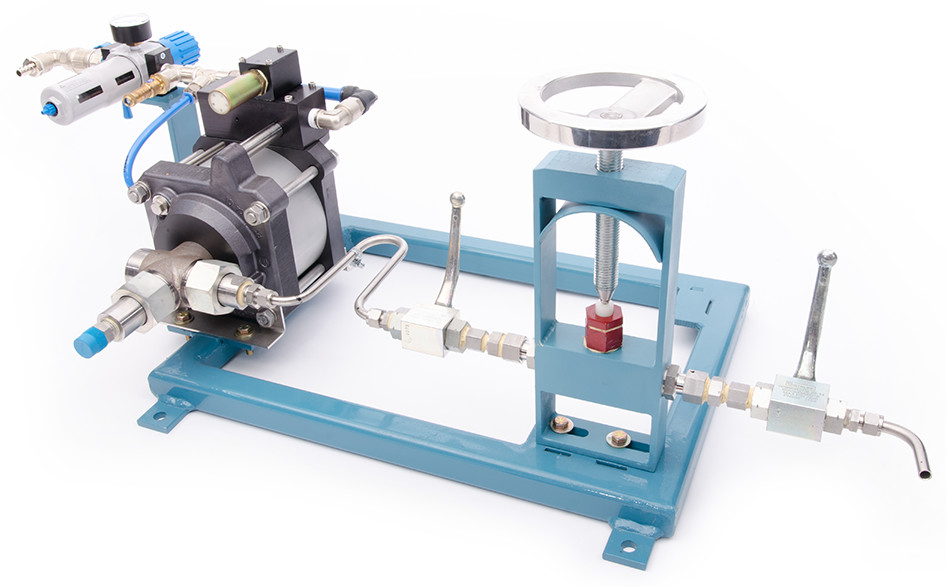

The Loading Table

Our Loading Table is ergonomically designed for the assembly and disassembly of tubes. This is accomplished with our 360 degree vice that safely holds the tube while allowing the operator to rotate the tube position. The table accommodates all of the necessary tools allowing the operator to assemble or dissemble a tube in just minutes. Fabricated with the highest quality components and built to last.

How it Works

The Pressure Gas Tube (Cardox) is loaded with a chemical Pressure Gas Generator and then sealed with the Tube Head. The Discharge side of the tube is loaded and sealed with a Copper Washer and Shear Disc, followed by a Discharge Head. After the tube is loaded it is then filled with liquid CO₂. Once the tube is loaded and filled with liquid CO₂ it is now ready to transport to the application for removing material build up.

A bore is created in the problematic buildup that is to be removed at the Base Socket location on the vessel wall. Once the bore is in the material, the tube can be inserted at the proper depth and is safely held with the Gripcase (counterpart to the Base Socket).

When detonated, the Chemical Generator creates heat, converting the liquid CO₂ to Gaseous CO₂ in 20 milliseconds. It expands at over 500 times its original volume and the gas ruptures the shear disc as high as 37,000 psi, producing traverse forces up to 15 tons. The CO₂ discharge is deflected by the Discharge Head removing/dislodging the material build-up.